|

||

|

Offline vs Online cleaning. Cleaners react to hot and cool molds differently. Here’s how to choose the best mold cleaner to maximize productivity and product quality while protecting your investment. | ||

| ||

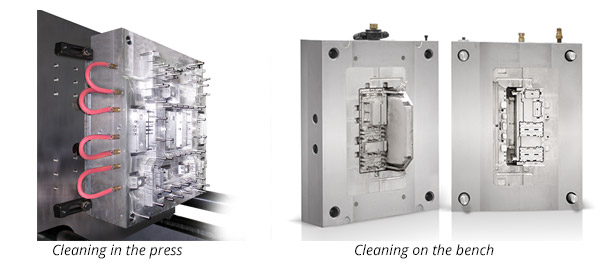

Injection Mold Cleaners: Hot & ColdCleaning molds is a key part of running a successful injection molding operation. But are you cleaning a cold mold, i.e. when the mold if offline, on the bench and at room temperature? Or are you cleaning a hot mold, i.e. the mold is warm and in the press? Cleaning solvents have formulations designed to work best at particular temperatures. For example, solvents that work well on a mold that is at room temperature are formulated to clean and evaporate at those temperatures. However, using the same cleaner on a warm mold will find the cleaner flashes off so quickly it doesn’t have a chance to effectively clean the mold. Solvents that work well at higher temperatures are much less aggressive and effective at room temperature. They take longer to evaporate or may even have to be wiped off. Using the wrong cleaner may result in poor cleaning or excessive time to accomplish the job. Cleaning a cool mold. The requirements of offline cleaners are primarily to dissolve resins, grease, oil, mold release and sometimes rust. These cleaners generally are required to have a very fast evaporation rate. They can readily dissolve greases and oils by merely flushing the mold with a heavy spray from top to bottom. Mold releases and resin build-up may require scrubbing the mold with a cloth saturated with the cleaner, such as pre-saturated mold cleaning wipes. The advantages of using such a cleaning wipe include: 1) Guaranteed sterile, lint-free and clean cloth 2) Ideal for precision cleaning 3) Pre-saturated with the ideal amount of cleaning solvent 4) Easy-to-use and non-hazardous disposal A final option for offline cleaning is the use of a mold polish and cleaning compound. These products are typically used in paste form and require manual application and removal. The typical mold polishing paste contains a combination of cleaning solvents and mild abrasives that are designed to aid with the removal of all contaminants from the mold or die surface. An added benefit of using such a polishing paste is the resulting sheen or luster that is generally left on the mold surface. Such a finish serves as a natural lubricant and release, thus minimizing the need for a mold release to be used later once the mold is put back into production. Cleaning a warm mold. Online cleaners are generally used to remove mold release build up, plate out of resins and light rusting of the mold. Often molds get plate out, which is due to the adhesion of resins [acetals such as Delrin® or Celcon® have been common offenders in the past] or fire retardant materials. Such build-ups must be chemically removed from the mold surface in order to minimize potential part deformation. A resin-removing product can chemically work to break down the material and to aid with the removal of the unwanted resin from the mold surface. As a general rule, cleaning solvents used on a warm or hot mold should be much slower evaporating. This allows for the chemicals to remain on the mold surface for longer periods of time, thus maximizing the cleaning potential. Test before you buy. Slide encourages you test our products. Free samples of all Slide products are available online at Slide Products web site. Slide Products has an extensive network of local distributors available to aid you with your product selection. Learn more about mold releases, cleaners and rust preventives | ||