|

||

| ||

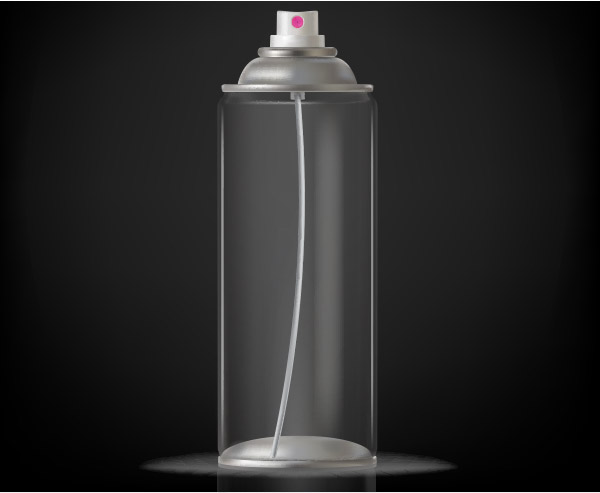

How Aerosol Technology Increases Plastics Processing ProductivityAerosols may seem like the same spray can that has been around for decades. However, advances in technology paired with its built-in features help your processes in a variety of ways. Tailored performance Let’s start at the tip. Aerosol can tips are carefully selected to deliver the optimal volume and spray pattern. For example, some mold cleaners work best delivering a forceful, narrow stream quickly removing grease and contaminants without wiping. A rust preventive, on the other hand, should deliver enough material in a softer, wider pattern to thoroughly coat and cover metal for long-term protection. Inside the can, the valve and tube are selected to ensure the flow is regulated so the right amount of product reaches the nozzle, and the entire assembly works properly until every last drop of active ingredient exits the nozzle. And have you noticed the concave bottom of the can? The long tube stretches down past the upward pitch into the lowest point, reaching every last drop of active ingredient. Built-in convenience This may seem obvious, but some manufacturers overlook this simple advantage. You can easily pick up a can of aerosol and move it from station to station. Bulk liquid is going to be heavier and clumsier to move around. In addition, bulk product needs additional equipment, like specially-approved containers, hoses and spray nozzles. And you can’t re-use containers, especially if you want to changing chemicals, without safely, thoroughly cleaning all components. A complete package...no mixing required Aerosols are simple, compact, pre-mixed containers, ready to use when you take off the cap. Easier to store Consider local fire regulations. How you store aerosols is completely different than bulk products. It is likely you already have facilities that meet NFPA and local fire regulations when using aerosols. Your storage room has the needed fire suppression system, door, walls, etc. that are required. Adding bulk product to the mix could require you to meet a whole new set of codes. So, before you look at migrating to bulk/liquid product storage and dispensing, consider all the factors. It’s not just cost of bulk vs. aerosol, it is the productivity and additional investments required that make a real difference in value. Slide Products is best known for its aerosol products. But we do have various formulations available in bulk. Feel free to contact our technical personnel to help you make the best choice for your particular application. Learn more about mold releases, cleaners and rust preventives |

||