Mold Release, Cleaner & Rust Preventive White Papers

Molding PVC (Poly Vinyl Chloride) presents a processor with a host of important issues. Heating results in the outgassing of hydrochloric and hydrobromic acids. These acids cause varying levels of discomfort for operators and can lead to pitting, oxidation, and other problems with a mold, die or other metal machinery in the vicinity.

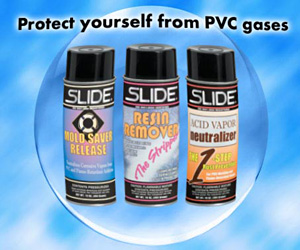

Slide helps you fend of the attack with our Trifecta of PVC Products – Mold Saver Release Agent, Resin Remover, and Acid Vapor Neutralizer. Using this combination of Slide products will help eliminate acids and provide protection against potential damage.

Step 1: Mold Saver Release Agent is a combination release agent and acid neutralizer. A unique release formulation that utilizes a non-silicone, paintable release oil, it won’t interfere with post-molding decoration of the finished part. To this release oil we add a powerful base material that constantly works to neutralize the acids as they are being emitted from the PVC resin. As you reapply the mold release, the neutralizing agent is strengthened to provide constant protection against the acids.

Step 2: While molding PVC, the release of the acids can lead to plate-out and resin buildup on the tool or mold surface. Slide Resin Remover (aka “The Stripper”) provides a quick and easy solution to aid with the removal of this problematic resin. Resin Remover is a production product, designed to be used with the mold still in the machine and a surface temperature above 175’F. The chemicals in Resin Remover work with the heat to break down and soften the old, unwanted residue. After approximately 90 seconds, the mold is put back into production. The fresh resin injected into the mold cavity will combine with the unwanted resin material and strip it from the mold, leaving behind a clean, residue-free surface. Using Resin Remover saves time and money as compared to taking a machine out of service and sending the mold to the tool room for manual cleaning.

Step 3: The final PVC offering from Slide is Acid Vapor Neutralizer. This is a rust preventive product that offers protection against not only moisture corrosion, but also against corrosion and oxidation caused by the presence of hydrochloric acid. Imagine a mold that has been closed up for storage, trapping large amounts of the acids inside the mold cavity. Without a specialized product such as the Slide Acid Vapor Neutralizer to help neutralize the acids, that mold will corrode with major pitting problems that require expensive repairs. Acid Vapor Neutralizer will provide protection against these acids for up to two months, protecting your mold or die investments.

Using an effective processing aid like those offered by Slide will help to increase your manufacturing efficiency and decrease your overall costs. Here at Slide, we fully encourage you test out our products. The best way for you to know that the Slide products are as good as we say they are is to get them in your operations. Trial Samples of all Slide products are available online at http://www.slideproducts.com. And unlike many other companies offering these processing aids, Slide Products has an extensive network of local distributors available to aid you with your product selection. If you are interested, please email your request to Slide Products.

GET EXPERT ADVICE ON INJECTION MOLD RELEASES, MOLD CLEANERS, RUST PREVENTIVES, EJECTOR PIN GREASE AND PURGING COMPOUNDS