This NSF ejector pin grease is essential to preserve the life of your injection molding tools.

This mold assembly grease is available in aerosol and non-aerosol formulations. Slide Super Grease is a colorless, odorless, paintable, NSF-registered (food-grade) ejector pin grease that works at high temperatures without melting. Super Grease works well with injection molds, mold assemblies, and especially medical and food-grade plastics.

Super Grease is ideal for medical applications (NSF-registered) and will not melt and bleed out into the mold cavity. It also has excellent dielectric strength.

Prevent Ejector Pin Problems

To prevent galling, seizing and pitting caused by thermal and viscosity breakdown, ejector pins must be carefully maintained using the right grease, applied correctly. The wrong grease or improper application can damage a tool and cause bleed-out onto the tool surface – which can lead to defective plastic parts.

How To Apply Right Ejector Pin Grease

Slide Super Grease for ejector pins is available in both aerosol and non-aerosol formulations to make application easy and effective. It will hold up in the heat, help prevent galling and when properly applied, will provide maximum lubricity without part marking. Read More...

#439

Super Grease, Clear, High Temperature

#483

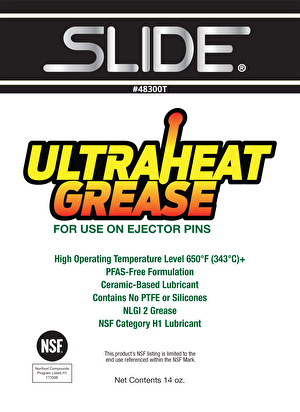

UltraHeat Grease, High Temperature Pre-Order

Answers are just a click or call away!

A Slide Purging Expert will contact you before your samples are shipped to ensure you receive the best product and quantity for your specific purging needs.

Consent has been revoked on one or more services. In order to fully activate that change the page must be reloaded.