January 6th, 2026

PFAS in Manufacturing

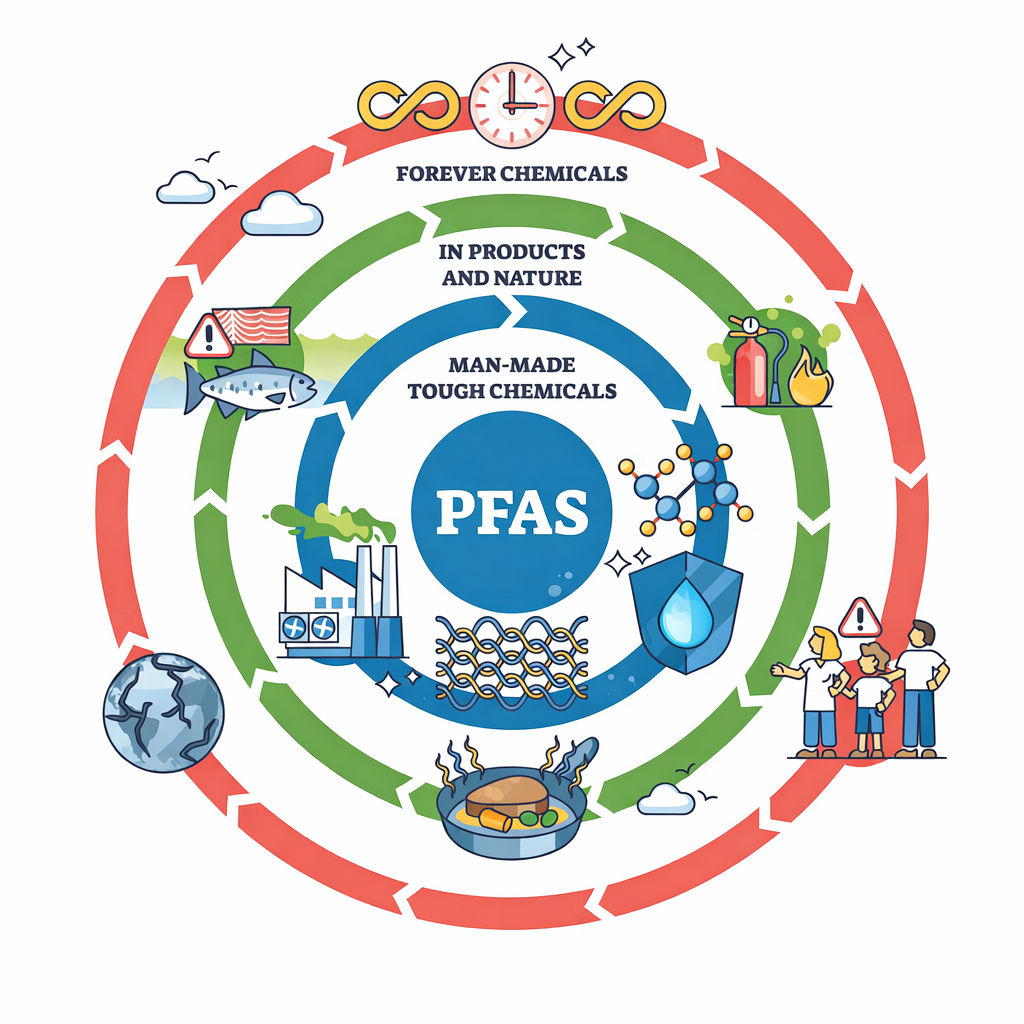

Per- and polyfluoroalkyl substances, commonly referred to as PFAS, are historically known for their important role in the plastic injection molding industry and have been used for decades in products such as mold releases, agents, coatings and maintenance aids.

Comprised of man-made, carbon-fluorine bonded chemicals, they possess beneficial characteristics that allow for the creation of products with benefits such as:

- Strong temperature stability

- Chemically resistant

- Degradation resistant

- Low-friction properties

- Water and oil repellency

Although these solutions offer attractive performance advantages, those same properties are what make them persistent. As research expands, the negative impacts have become more apparent, and manufacturers are increasingly required to adhere to evolving regulatory standards aimed at reducing fluorinated chemical contact.

PFAS in Maintenance

In plastic injection molding applications, PFAS are most often found in servicing solutions including lubricants used on ejector pins, slides and other high-wear components. These areas get exposed to repetitive cycles, elevated thermal settings and tight tolerances, where lubricant breakdown can lead to galling, seizing and accelerated wear. Over time, inadequate greasing will increase downtime, cause unplanned repairs and negatively impact part quality.

Growing Concerns

“Forever Chemicals”

Once processed, these materials do not biodegrade. When released into environs, it is possible for PFAS to migrate into groundwater and ultimately re-enter the food chain through biological systems. Even products with a short life span, such as a candy wrapper only used for a few minutes, could leave a permanent environmental footprint when discarded.

Health and Workplace Exposure

Research has shown some serious consequences associated with this kind of exposure, including a greater risk of cancer, immune system disruption, and damage to the reproductive/hormonal systems. In addition to concerns for end users, manufacturers who consistently work with PFAS-containing products are often apprehensive.

Regulations

As awareness around this subject continues to grow, regulatory oversight is becoming increasingly stricter. Plastic processors have sounded the alarm and requested stronger scrutiny and reassessment of MRO products that were once considered standard. The industry regularly seeks alternative compliance with evolving regulations – without sacrificing performance or part quality.

Solutions and Alternatives

Previously, PFAS-free lubricants have struggled to maintain stability under extreme conditions and cycle rates, thus limiting necessary integration within important maintenance procedures. Innovative advances in technology and chemical formulations strive to deliver the same thermal solidity and effectiveness that these forever chemicals have traditionally provided.

For molding applications, particularly ejector pin lubrication, achieving a perfluorinated compound-free function has been a common challenge for many operators, especially in elevated heat and continuous operations.

Introducing Slide’s PFAS-Free Ejector Pin Grease

As part of our ongoing commitment to sustainable manufacturing solutions, Slide is releasing a new PFAS-free, high-temperature ejector pin grease formulated specifically for injection molding usage.

UltraHeat Grease Features:

- Superior operating thermal capacity (550°F)

- PFAS-free

- Exceptional mechanical and thermal stability

- NSF H1 registration

- NLGI 2 consistency

- Ceramic-based lubricant

- Contains no silicones

This ejector pin grease is engineered to perform under severe conditions, without contributing to long-term ecological or regulatory risks. It is designed to uphold lubrication consistency under accelerated run rates and elevated mold climates ordinarily used in plastic processing. This formula is designed for molders seeking a PFAS-free option without compromising reliability in high-temperature environments.

Try Before You Buy

Prior to being commercially available in Q1 2026, Slide is offering customers and distributors free pre-production samples to try now. Injection molders looking to evaluate a PFAS-free pin grease in real-world conditions are encouraged to request a trial sample before the official launch.