February 9th, 2026

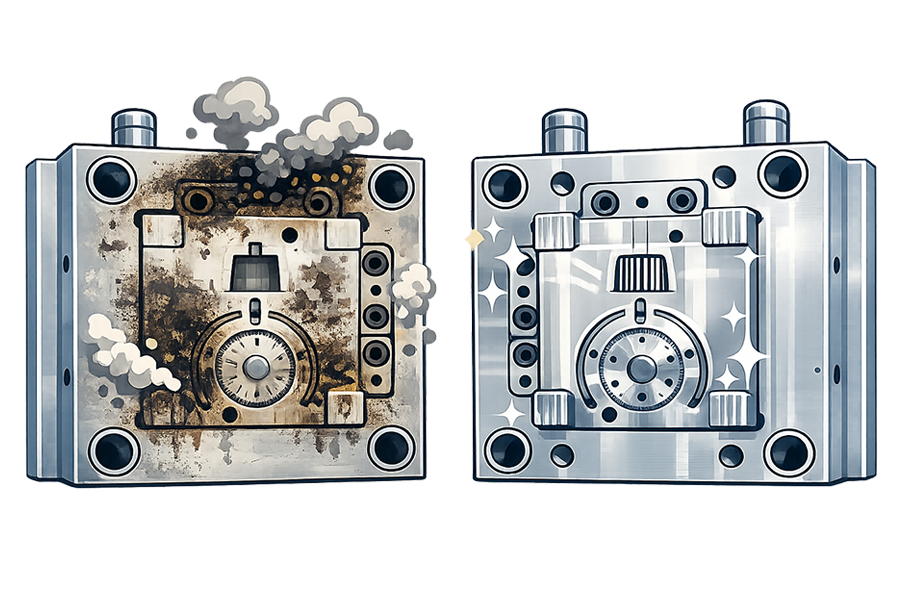

In plastic injection molding, “clean” is one of the most used and generally misunderstood words in the industry. A mold may look ready for production, but when put back on the line, flashing appears, parts begin to stick and gas burns show up – the issue often isn’t your processing settings – it's the difference between surface treatment and true mold revitalization.

Recognizing that cleaning restores appearance and function temporarily, but doesn’t chemically condition steel, is critical in extending tool life, improving quality and sustaining consistency during production.

What “Clean” Typically Means

For most technicians, cleaning means getting rid of what’s visible.

It’s a mechanical, cosmetic step designed to remove the “top layer” of contaminants that have accumulated during an injection run. This usually includes loose dust, excess grease from pins, fingerprints and light buildup.

For various processed resins, a simple wipe with a quality solvent is usually enough to keep machines working and prevent immediate contamination. Routine cleaning plays an important role in daily molding upkeep. However, high heat, strong pressure and complex resin formulations introduce possible complications a regular rag won’t even touch. When pollutants no longer lightly sit on the mold surface, and bonding occurs, wiping provides a temporary fix rather than a necessary solution.

What is Surface Recovery?

A chemical reset, beyond a quick wash.

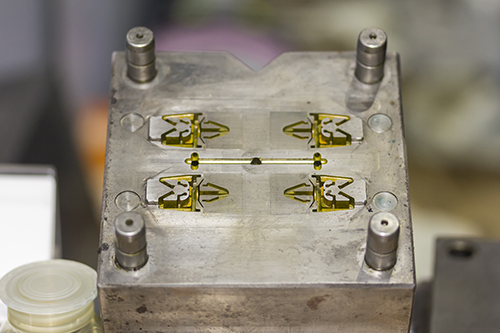

For every mold being run, outgassing is always a possibility. Materials like PVC, acetal (Delrin) and flame-retardant resins release corrosive vapors that go way beyond a light covering but adhere to the mold itself.

Recovery is not polishing, refinishing or reworking steel, it’s a restoration method to clear vents, revitalize mold release capability and repel corrosion. It breaks down unwanted molecular bonds thereby returning a cavity to its original, engineered performance.

How Outgassing Impacts Performance

Outgassing is inevitable in plastic injection molding, it's not a matter of if it happens, but what to do when it does. Below are three signs that your mold needs more than a routine wipe down:

Vents Won’t Open

Mold vents are designed to let trapped air and gas escape. When issues like clogging, short shots, burn marks and inconsistent filling arise, the cause isn’t always visible. In many cases, narrow venting channels become blocked by microscopic gas residue. A standard solution might remove impurities but fail to penetrate attached buildup that restricts airflow.

Lubricant Carbonization

High temperatures can cause lubricants to break down and carbonize, forming a hard crust hindering ejector movement and product adhesion. Renewal requires this layer to be stripped off entirely, so there won’t be any interference with new lubricants being applied.

Resin Ghosting

Often seen during color changes, ghosting takes place when deposits become embedded into the steel. Even after cleaning, traces of excess resins or colors can alter part appearance, finish or release function.

Hidden Consequences of “Just Cleaning”

Relying solely on a mold cleaner is usually the driver behind repetitive defects. When a mold isn’t properly maintained, processing proficiency continually declines. Skipping restoration can turn into:

- Repeating troubleshooting for the same problem

- Shorter run times and/or quality control issues

- More frequent equipment servicing

When Mold Recovery is Necessary

Regular cleaning is an essential step for daily maintenance, but recovery is necessary when:

- Defects reoccur right after cleaning

- Vents appear to open but continue trapping gas

- Release issues even after proper lubrication

- Color or resin changes keep on ghosting

- Maintenance intervals get shorter

If these problems persist, it usually means your contaminants are stuck, rather than sitting on the exterior. Such elevated safeguarding is not required after every run but should be done when performance lags despite using the appropriate formulations.

Financial Consequences

Increased Labor and Downtime

If a technician must stop the workflow every two hours for a “quick wipe”, it’s more than 10 minutes of wasted production time – it’s losing out on the momentum of your workflow.

Accelerated Wear

Even small amounts of resins left behind on a cavity can act as an abrasive. Over thousands of cycles, microscopic residue contributes to permanent wear and potentially substantial amounts of money towards unexpected restoration repairs or replacement.

Long-Term Benefits

Cost Savings

Being proactive about consistent and intentional machinery care helps to detect problems

before they materialize. Rigorously caring for each component ahead of any disruptions translates to:

- Extended tool life

- Reduced recurring defects

- Improved release consistency

- Prolonged maintenance intervals

- Protected mold exteriors from corrosion

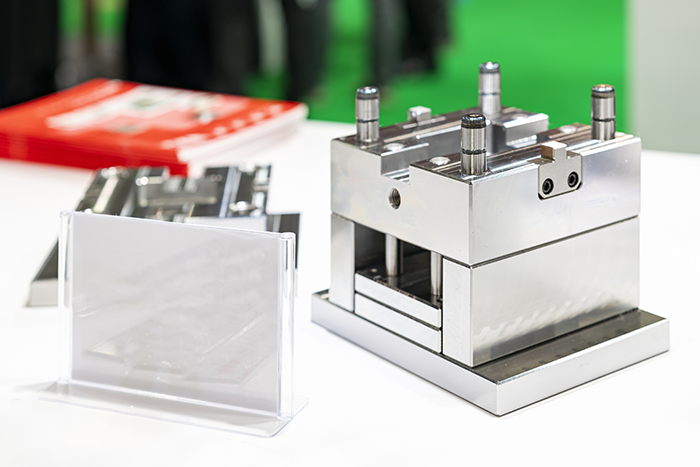

Integrating Slide Products Solution

At Slide Products, we have spent over 70 years focusing on understanding what happens to components in real world conditions. From our Mold Cleaners and Purging Compounds to high performance Ejector Pin Greases and variety of MRO products, our focus remains on supporting your manufacturing reliability and restoring mold integrity, far beyond making molds look pretty.