September 23rd, 2025

Have you ever wondered how it’s even possible for food containers or syringes to be made without a single speck of dust? It literally cannot happen without a cleanroom. This term refers to a highly controlled manufacturing area designed to limit contact with airborne contaminants. Instead of allowing particles to float freely, everything is monitored and controlled to meet strict precision and cleanliness standards.

Many products produced with injection molding techniques are used for human contact, body insertion or even space missions. By operating in consideration of this, items can be manufactured to attain the highest quality imaginable without the risk of impurities, and safe enough for use in sensitive applications.

Industries Reliant on Cleanrooms

Medical

Your neighbor’s knee replacement? Yes, you guessed it – cleanroom molded.

Implants, prosthetics, surgical tools and drug delivery devices

Aerospace

The satellite that enables your GPS? That’s made with cleanroom molding.

Optics, lasers, engine components and defense equipment

Food and Beverage

The coffee machine that starts off your day – a cleanroom made it happen.

Kitchen utensils, lunch containers, seals and caps

ISO Certifications

ISO is the international standard for quality management implemented globally to uphold manufacturers to certain regulations. When it comes to cleanroom settings, the ISO 14644-1 standard measures the number of particles present in the air.

ISO Classes and What They Mean

The ISO classes range from 1-9, with ISO 1 being the cleanest and ISO 9 the “dirtiest” (which is still more favorable than a regular room after a more comprehensive cleaning). The lower the class number, the smaller number of fragments allowed.

Cleanrooms rated ISO 1-6 are designed for manufacturing items related to biotechnology and cutting-edge research tools like tiny microchips, where even micron sized particles are a factor. For most medical, food and pharmaceutical cleanrooms, class 7 or 8 is the standard.

Class 8

- Can be accessed without an airlock (an enclosed space to prevent particle transfer) but most always requires a gowning room.

- 20 air changes per hour minimum.

- Allows a maximum of 3,520,000 particles per cubic meter that are 0.5 micrometers (µm) or larger in size, 832,000 particles per cubic meter that are 1 µm or larger and a maximum of 29,300 particles that are 5 µm or larger.

Class 7

- Often requires an airlock transition and gowning area.

- 60-90 air changes per hour using high-efficiency particulate air (HEPA) filters.

- More restrictive, allowing for 352,000 particles per cubic meter of 0.5 µm or larger, 83,200 particles >1 µm and 2,930 particles >5 µm.

Key Requirements

Air Filters

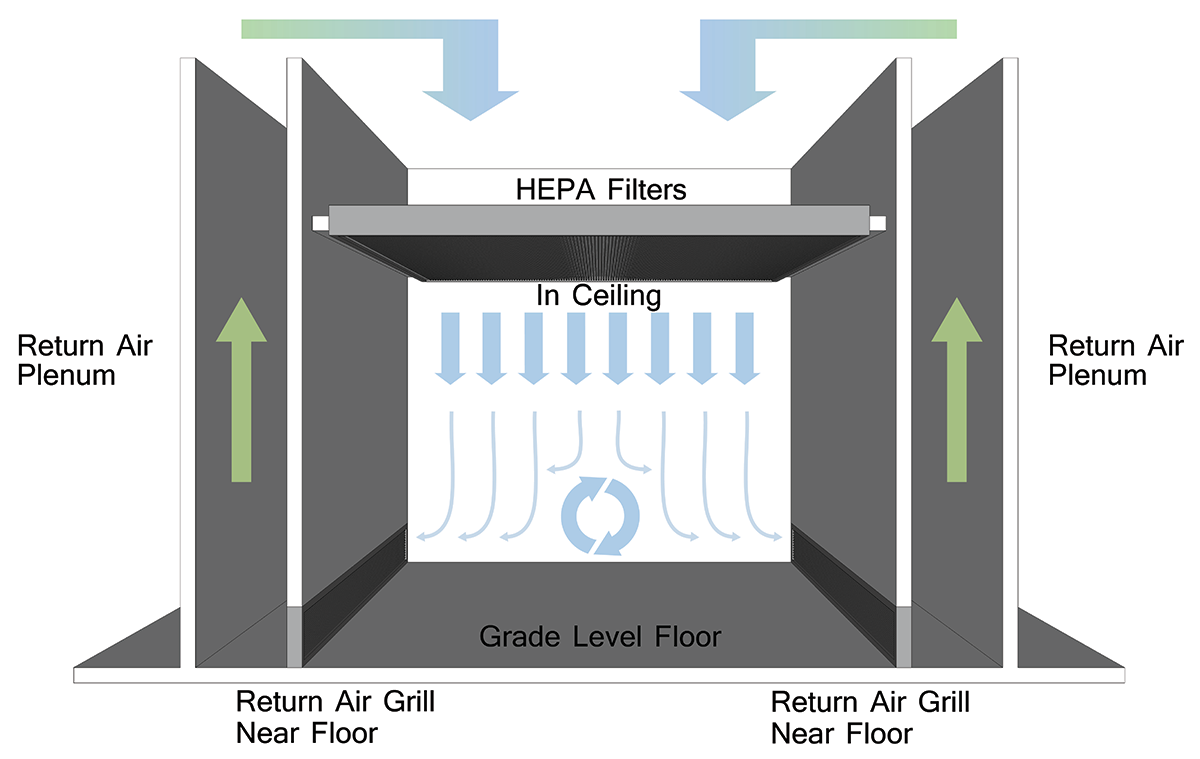

- In any cleanroom environment, air is constantly recirculated and filtered, which is initiated by ULPA (ultra-low penetration air) and HEPA (high-efficiency particulate air) filters.

- These are the brains running the show – HEPA fans and ULPA filters are usually installed on the ceiling for drawing in particles to remove them, purifying the air.

Controlled Environments

- Advanced HVAC networks, comprised of particle counters, temperature sensors and pressurized controls between zones keep things in check (the “babysitter” in the room).

- These systems not only track air and pressure but can also alter temperature and humidity – which is directly related to product integrity.

- High pressure is kept inside of the space, and forces air out when the doors open to prevent a consistent airflow between rooms.

Surface Finishes

Having surface elements that deter debris from finding a place to hide are a must. Some common finishing forms contain the following characteristics:

- Non-porous coatings – the smoother the better!

- Easy to clean walls and floors

- Stainless steel materials instead of woods

User Protocols

Let’s be real – we, as humans, are the biggest source of contamination in a cleanroom. This means there needs to be adequate training to inform workers on the risks and how to follow the appropriate procedures.

Workflow

- Strategic workflow is incorporated to separate “dirty” and “clean” areas – chambers are often used for transporting items like raw materials passing from one room to another.

- Airlocks can also be found in these scenarios, when only one door is opened at a time, so that when someone enters or exits the work room dirt can be blocked from hitching a ride.

Sterilized Apparel

- A separate area for dressing containing airlocks is known as the gown room, which is typically located just before entering the actual manufacturing hub.

- You will always find special garments in this environment that never leave – shoe covers, face masks, gowns, gloves and hairnets.

Documentation

- From start to finish, detailed documentation is necessary to oversee the entire process for maintenance, calibration and training purposes.

- Logging each stage helps to ensure accountability and transparency.

Special Injection Molding Equipment

All Electric Presses

These machines make it possible to eliminate the need for hydraulic fluid. No fluid means no chance for leaks and no messes left behind.

Contained Components

Everything in this machine is securely enclosed so the molding area is the only access spot. All moving parts and pieces are sealed to avoid releasing particulate matter into the space.

Robotic Assistance

As humans are the biggest threat for contamination, using programmed robots to facilitate all movement, from the conveyor to packaging, means nothing ever gets manhandled.

The Best Formulations for Cleanroom Operation

Rule #1: You should never, ever use an aerosol – one spray can send particles flying everywhere. Instead, stick with reliable solutions that keep your area protected, such as lint free wipes and application methods allowing more control.

Guidelines for Choosing Safe Products

NSF registered category M1

Signifies a product's suitability for using certain mold release agents or lubricants in food processing areas.

Isopropyl alcohol

Highly concentrated, IPA is often applied from a spray bottle or by hand.

Food Grade

Safe for direct or indirect contact with food, non-toxic and won’t leach out harmful substances.

Cleanroom injection molding is not just a process, but a commitment to the highest standards of purity and safety for manufacturing. From the coffee machine that starts your day to the medical device that could save your life, every filter, practice and standard involved protects the products we rely on daily. The steps and dedication for ensuring measures are met means products can be produced for the vital industries that need them.