June 10th, 2025

The adult toy industry is rapidly evolving – driven by inventive techniques and sustainability, and a sharpened focus on efficiency and user enjoyment. At the heart of this sector lies plastic injection molding – a fundamental process that enables precise, high-volume production and implementation of these innovations. From conception to consumer, injection molding has helped supplement personalized designs, well-being, novelty, inclusivity and accessibility thus forming the backbone for this niche supply chain.

Market Overview

Originally crafted from stone roughly 2,800 years ago, these erotic accessories have experienced a surge in popularity due to modern manufacturing methods. In more recent years, as of 2024, the US market for sex toys was valued at $10.6 billion and is projected to reach $17.11 billion by 2030, reflecting a growth rate of nearly 8.38%. The increased demand has been made possible in part through plastic injection molding.

The Manufacturing Process

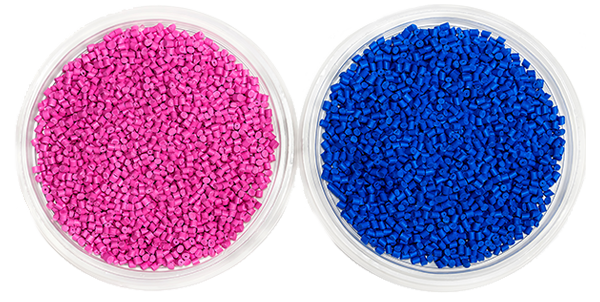

Liquid injection molding is ideal due to its ability to create ergonomic, body-safe components and intricate details made to be highly repeatable. A mixture of silicone and pigments gets combined with a catalyst. As a chemical reaction occurs, the mix is extruded out of pipes into a mold. Spacers help to create its shape, (such as a vibrator) where it cools and cures into a solid object. Once the product is finished setting, demolding takes place, releasing it out of the mold cavity. Fine tuning is the last step to make sure there aren’t any raw edges before getting packaged for retail distribution.

Key Benefits

Design Flexibility

Complex geometries and integrated features can be achieved by utilizing internal nooks for precision work. Characteristics such as ridges, curves, studs and other fine detailing meant for stimulation can be added to customize any toy. Some options include soft or hard gels, vibrant colors and funky textures.

Seamless Output

This process supports a smooth flow of composites into a single-piece construction, thereby reducing areas where bacteria may collect. This aspect is critical to safety during use of intimacy aids.

Cost Effective Repeatability

After tooling and prototyping to near perfection, novelties can be made in highly economically consistent batches at very large, repetitive quantities. PVC and jelly rubbers are often inexpensive to produce and easily moldable but should be treated properly to be as non-toxic as possible.

Prototyping and Design

An essential step in operation involves turning ideas into tangible solutions. Prototypes developed in a series contribute to exploring options that can be refined before pursuing broader manufacturing.

- A combination of 3D modeling, CNC machinery and soft tooling produces an initial mimic of the intended outcome without the cost of hard tooling.

- Identifying elements and all included components for calibrated adjusting enhances the likelihood of meeting aesthetic and usability expectations.

- Rigorous testing is key to durability, performance and effective design for optimum user experience.

Certifications and Compliance

For many of the leading sex toy companies, safety and regulations are not always incorporated due to the fact packaging may be labeled as “novelty items” and often vaguely designated for “non-body use”. This predicament can cause issues for buyers dealing with chemical compositions that could cause itching, burning and even tissue damage. When shopping for a toy, be aware there are certain standards that might make one product more trustworthy than another.

More Dependable Materials

Medical Grade Silicone

“MGS” is easy to clean, non-porous and usually compatible alongside most lubricants (excluding some silicone lubes). It’s pricier but available in many textures and colors.

ABS Plastic

Body-safe, pore free and durable, this pick is more affordable than silicone and perfect for items like vibrators. Hard in stature, it lacks flexibility and is often slippery when wet.

Metals (stainless steel, titanium, gold, silver)

Extremely sturdy and often expensive, metals can be made secure for personal use if avoiding cheap alternatives like nickel, which tends to cause an allergic reaction.

Materials to Avoid

Phthalates

Utilized to make plastic more malleable and softer, phthalates are linked to hormone disruption, fertility issues and might leak out of an intimacy device over time, posing health concerns.

Jelly or Rubber

Highly porous and difficult to clean, this material provides a breeding ground for bacteria buildup, causing infections. Not suited for the body, these formulas are easily identified by their strong smell and should be replaced with an ABS or silicone option.

PVC (polyvinyl chloride) and TPE (thermoplastic elastomer)

Hard to sanitize and prone to degrade over time, both can lead to rashes and burning. Even when labeled “phthalate-free”, toxic additives like phenol or cadmium might be the culprit for such results.

Future Trends in Manufacturing

While manufacturing continues to progress towards seeking better solutions that are more efficient and deliver dependable products, companies are exploring opportunities for better quality output. To help these businesses flourish the following approaches are essential:

Increased Use of Automation

Automation is used to speed up production, while incorporating smart features and improved performance. Robotics and conveyor belts streamline assembly to generate mass outlay during repetitive tasks of molding and packaging. Automation warrants safety and minimizes human error by ensuring accuracy.

Advanced Material Development

With a promising strong market trajectory, some companies are expanding research into reliable silicones, non-toxic, and hypoallergenic products.

Personalization

The industry furnishes to diverse consumer preferences that prospers on advancement and individuality. Feedback from consumers brings about forward-thinking ergonomic designs, diverse selections and additional special features. This helps strengthen brand loyalty and improve customer approval.

Smart Technology

Interactive gadgets are being developed with the use of advanced technology, reshaping the utilization of these products. Mobile apps give users access to change settings like intensity, vibrations and patterns from the touch of a button.

Case Study: Slide Product Solutions

“It didn’t freak me out what they were making, but the quantity they were making -it blew my mind. We are not talking about 5, 10 an hour. We are talking about hundreds or thousands an hour.” – Juan Grino, a Slide expert, had an opportunity to see the operation in person. He experienced a full line production run, watching thousands to millions of these products being produced in a single day.

Juan was able to provide the company with a solution to a silicone heavy oil residue with Knock Out Mold Release (#46612N) – a glycol-based aerosol to get rid of any leftover oil.

Currently in the USA, there are a couple hundred manufacturers supplying this nuance category. In conjunction with plastic injection molding and an expected boom, there’s a potential of revolutionizing the marketplace. Juan Grino goes on to state “A typical American residence has up to 10 devices per household in a lifetime. These companies are heavily invested in research, and we can expect to see a boost in available products with the development of ground-breaking technology, experimental materials and personal touches. This is not just an industry, but a billion-dollar one that’s growing fast.”