November 18th, 2025

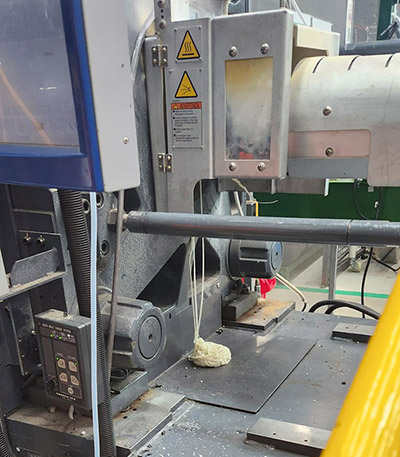

As production ramps up near the end of the year, many molders feel the same pressure dealing with constant color changing, back-to-back runs and zero margin for downtime. Properly managing pigment transitions becomes critical, particularly when running those bright, high opacity seasonal hues.

That’s where a purging compound becomes imperative – the secret weapon that keeps large scale manufacturing operations flowing merry and bright. During heavy production cycles, purging is a reliable maintenance solution for clearing out color and carbon build up between production runs on areas like screws, barrels and hot runners. By incorporating this simple step into your process, you’ll reduce material waste, prevent contamination, maintain consistent output and stay ahead of competitors.

Why Purging Matters More During Peak Times

As orders pile up and deadlines tighten, small interruptions can snowball into major disruptions. When handling pigmented or specialty resins, transfer and contamination risks skyrocket and issues will inevitably compound if machines aren’t properly purged. Common challenges that will crush the holiday spirit:

Color Bleed

Going from a dark to lighter shade?

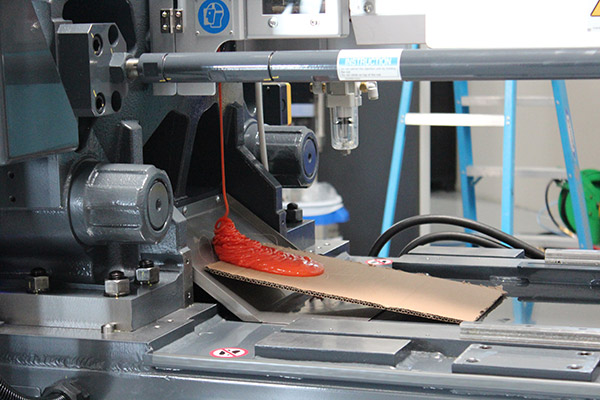

Even if it’s just a trace amount, any residual colorant from previous runs can linger and cause streaking, patching or off-toned part appearance. Metallics and specialty tints tend to cling tighter to screws, barrels, walls and hot runners, making dark to light conversions especially sensitive to carryover. The mix of red and green might look festive, but not when it’s unintentional and adds to scrap rate.

Gate Blush

Switching between clean and opaque materials?

Without a thorough purge, overheating, improper fill speeds and impurities create cloudiness and poor surface quality, instead of the cheerful appearance you were hoping for. This discoloration is most common in thin-wall and high clarity parts. A clean transition will provide you with a crisp, consistent finish.

Resin Degradation

Getting ready for shut down?

Long runs that entail extreme heat can result in resin burning or even carbonizing in the machinery, leaving behind unwanted residue. This happens more often during extended runs of colored resin, so purging should be done to remove any leftover remnants.

Extended Downtime

Every minute counts.

Oxygen and increased heat accelerate buildup inside the barrel, leaving behind carbonized resin. Using a heat-stabilized purging compound eliminates shutdown time by minimizing the need for excessive and time-consuming manual cleaning.

Best Practices for Efficient Purging

Purge Between Every Color Run

Don’t wait for defects to happen. Regular preventive purging between runs makes changeovers predictable and reduces product waste.

Purge Before and After Cycles

Plan to utilize this cleansing solution both at the start and the end of each batch run. It will keep the barrel tidy during idle periods and maintains material integrity for the next startup.

Choose the Right Compound

Not one size fits all – each purging compound is designed differently, so pick one that’s most compatible with your specific equipment and resin type. Read the label before application to certify the specifications meet your project restrictions.

Verify Temperature Parameters

To prevent carbonization from occurring on larger jobs, purging should be done at the same temperature as the last processed material. After the barrel is cleaned, lower the temperatures slightly for shutdown to prevent oxidation.

Documentation

Create a detailed list to keep track of your purging intervals, which compounds were utilized and each shot count. This helps to refine the procedure over time to reduce variability.

Additional Pro Purging Tips

- Hot Runner Systems: Color failures are usually attributed to the purge material not reaching all channels in the hot runner.

- Forward/Reverse Screw Controls: Quickly short forward and reverse screw cycle techniques will aid in removing more stubborn resins, like metallics.

- Trial Run: Run a small batch of test shots after purging to verify aesthetic integrity.

Get the competitive advantage this busy season by implementing the key MRO product for efficient color changing – a purging compound! Slide offers a helpful cost savings tool to assist in determining the true cost of your purging procedure.