December 23rd, 2025

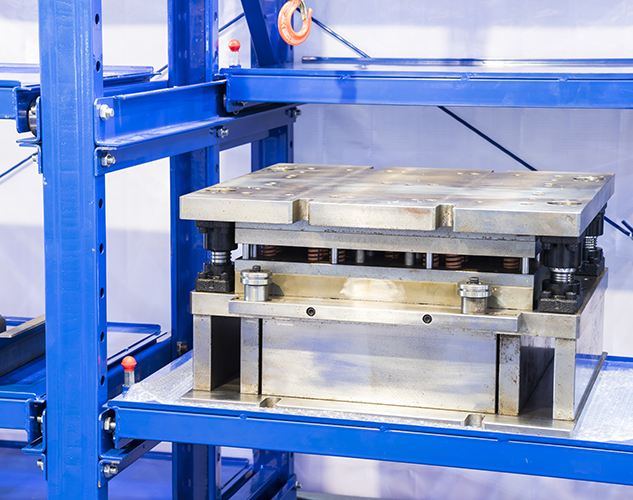

Experienced molders pretty much understand the basic steps involved in this kind of maintenance procedure, such as purging the barrel, running the screw and coating the mold. But seasonal shutdowns for winter can bring on a whole set of unique issues. Simply switching off heaters and emptying the barrel just isn’t good enough.

Cold weather shutdowns come with complex risks – delays, higher scrap rates and potentially extensive repairs – all driven by winter conditions like thermal shock, condensation and corrosion. Utilize this guide to keep your molds protected and eliminate surprises when it’s time to get them back online.

Initial Steps Before Storage

Reduce Screw Speeds

Lower the screw speeds to 15-20 RPM. As the material slows down at the nozzle, stop the rotation to reduce drippage and leftover resin.

Use Purging Compounds

Surplus resin in the hot barrel is an invitation for thermal decomposition and carbon buildup. Purging compounds will remove any remnants from the previous run and should be used immediately after the last shot. Keep in mind that “virgin” or DIY purge solutions aren’t as effective as a commercial formulation.

Clean and Neutralize Chemicals

Use a high-quality mold cleaner solvent and apply it generously to the core, cavity and parting lines. Let the solvent flow onto each part where it will remove residual grease, oil and gas. For stubborn resin deposits or oxidation, a low-abrasive polish will restore your surface without screwing up part dimensions.

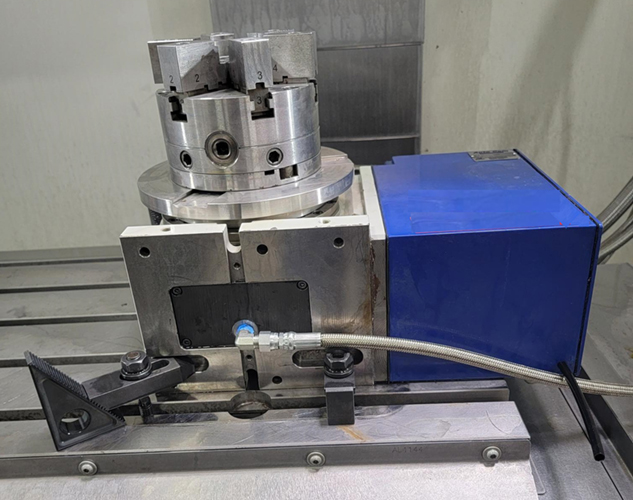

Contain Moving Components

Retract and seal any moving parts, then lubricate each with a high-temperature ejector pin grease on the slides, lifters and leader pins. This will fight off moisture-related decay and galling (seizing) while the mold is idle.

How to Store

Manage Dew Point and Humidity

When a hot mold is placed in a cold room too quickly, the metal rapidly drops below air saturation levels, producing condensation on its surface. Those tiny droplets subsequently get absorbed and when heated during processing could create bubbling, pitting and flaws. Keep humidity in check to prevent liquefication from forming initially.

Control Temperatures

The fewer temperature swings, the better. The goal is to simply keep the mold above the room’s dew point. Pick a climate-controlled environment or use a dehumidifier inside enclosed storage spaces.

Prevent Corrosion

Apply a tooling-grade dry film that “flashes off” at startup or contains oils that form a protective barrier. Self-cleaning rust preventives are also available, so you can skip the stripping and recoating step before production. Such formulas should be sprayed very lightly on the cavity, since thick layers can trigger unneeded cleanup and blemishing.

Seal Fluid Lines

Cooling lines must be drained, blown out and capped. These channels are notorious spots for moisture to hide and become trapped, possibly leading to expensive internal deterioration and line replacement.

Label and Document

To save time on your next startup, make notes regarding the last resin that was used, any repairs, solvents applied and where the tooling is preserved.

Before Next Start Up

Transition to Room Temp

Bring molds to a room temperature workspace to let them “settle” and reach a neutralized state. This prevents dampness from forming on the piece as it warms and eliminates thermal shock.

Remove Rust Preventive

If you used a wet oil, follow the instructions on the product label. If your product contains a “flash-off” film, it should self-clean upon startup, but always run a test shot to be sure.

Dry and Inspect

Do a thorough check to confirm there aren't any signs of pitting, residues or wonky movement of ejector systems and slides. You can spin the ejector pins and examine frequently attacked areas (welds, thin radii, complex geometry) where corrosion is most likely to be found.

Warm Up and Purge Out

Heat the mold and machine to the appropriate temps and purge out any remaining films or residues before loading in another material. Watch for contamination signs and adjust purging intervals as necessary.

Slide Products offers high quality, specialized formulations for complete seasonal mold storage solutions.