November 4th, 2025

The cost of downtime in injection molding involves more than lost parts; it depletes overall productivity, profits and efficiency. In fact, manufacturers estimate about 30% of annual production capacity is lost due to unplanned breakdowns.

MRO (Maintenance, Repair and Operations) products are essential for keeping equipment running smoothly and ensuring the highest-quality parts. These products and tools do more than just support machines – they sustain every facet of the entire operation. Maximize your equipment life and keep your components in top shape by incorporating the right maintenance options to protect your investments.

What is MRO in Manufacturing?

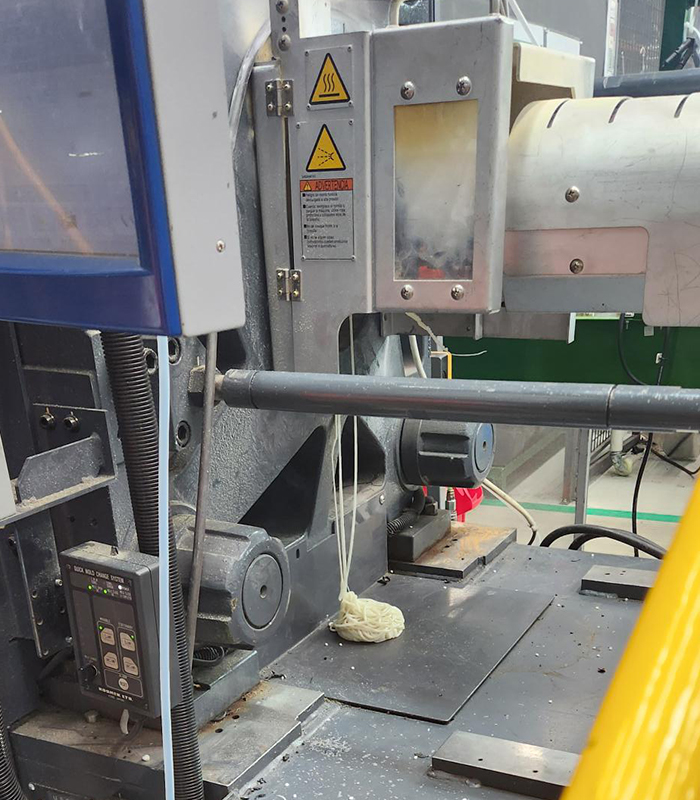

MRO for injection molding include chemicals, spare parts and any supplies that aren’t a piece of the final mold output and critical for optimal processes. Instead of serving as a quick fix to an existing problem, they are key aspects of preventive steps to avoid things going rogue.

Even though the cost is minimal, the return on investment can be exponential. Effective MRO helps to minimize scrap rates, lessen cycle times, extend mold life and enhance overall efficiency.

Common MRO Product Categories:

- Lubricants and Grease

- Mold Release Agents and Cleaners

- Purging Compounds

- Rust Preventives and Corrosion Inhibitors

- Anti-Seize Compounds

- Cutting/Tapping Fluids

- Penetrants

- Silicone Emulsions, Degreasers and Solvents

- Replacement Parts (sensors, ejector pins, heater bands)

- Maintenance Tools (polishing stones, brushes)

Choosing the Right Product

When selecting the best maintenance solution, your choice is dependent on the resin type, environment and processing conditions. Below are some of the key properties to consider when evaluating the most suitable solvent:

Residue and Cross Contamination

For food-grade, high-tech or precision molding that doesn’t leave room for any impurities, residue-free formulations are crucial. These products are often labeled as “no residue” “non-staining” or “quick evaporating.”

Such formulas ensure compatibility with:

- Paint adhesion, surface coatings and finishing

- Food and medical applications (NSF-registered category H1)

- Overmolding and secondary bonding

Thermal Stability and Resistance

Injection molding operates under high temperatures and extreme pressures, so agents need to be formulated to withstand such intense conditions.

- High-performance resins such as PEEK, Ultem and PPS require thermally compliant products.

- Always verify that the heat ranges listed on the label match your working conditions.

Cycle Time

The whole goal of MRO is to decrease downtime, so pick a product that acts fast.

- Use cleaners that contain “fast flash” or “easy rinse” features for quick changeovers.

- Release agents should provide smooth, even coverage without requiring thick coatings or constant reapplication.

Corrosion Protection

Metal parts will inevitably rust if they aren’t properly cared for – that’s where rust preventives and shielding come into play.

- Select products designed to repel water, displace moisture and leave a protective film.

- Some formulations are self-cleaning at startup and effective in neutralizing fingerprint acids for extra safekeeping.

Resin Compatibility

Lubricants, mold cleaners, purging compounds and mold release agents must be suitable for the resin being used.

- Poor matches can trigger chemical reactions, degrade seals or cause migration into mold cavities.

- Always review compatibility using specific documentation or SDS to confirm appropriate choice.

Compliance Standards

Medical, food and cleanroom sectors require strict formulation requirements to adhere to regulations.

- Look for NSF, FDA and low-VOC certifications

- Non-toxic, environmentally safe formulations have increasingly become the industry standard.

Environmental Concerns

As manufacturers move toward stronger eco-conscious approaches, using greener solutions has become more important than ever.

- Water-based and biodegradable options support ecologically sound initiatives without sacrificing performance.

- Products in line with these goals keep you compliant and competitive.

Technology

New formulations, advanced science and innovative packaging designs have modernized maintenance.

- You can now find solvents like “smart” lubricants that detect wear and temperature shifts.

- Controlled spray systems are available to minimize the risk of overapplication and waste.

Preventive maintenance costs pennies compared to expensive disasters. That’s why using the right MRO procedures can make all the difference in your entire manufacturing process. Don’t wait for system failure to strike – optimize your production and profitability with Slide Products today.

Searching for top quality MRO products? Look no further. We offer metal cutting fluids, rust preventives, rust inhibitors, plastic cleaners, greases, anti-seizing compounds and more.