July 22nd, 2025

In the world of plastic manufacturing, unplanned downtime and inconsistent part quality can translate to lost revenue and unsatisfied customers – making regular maintenance a crucial practice for success. Whether you are managing a big or small-scale operation, upkeep on your machines becomes essential to reduce scrap, extend mold life and maximize return on investment. Routine care is a proactive strategy as it identifies problems before they turn into costly disruptions.

Benefits:

Reduced Downtime

Scheduled procedures help prevent outages that slow or halt production.

Extended Mold Life

Regular care minimizes the likelihood of wear and tear on expensive molds.

Consistent Quality

Calibrated and maintained segments deliver high-precision outcomes.

Lower Scrap Rate

Addressing issues early on mitigates the risk of defective pieces and waste.

Improved Efficiency

Preserving equipment helps machines to operate efficiently and minimizes energy consumption.

Regular Inspection

During production all components involved influence a product's quality and machine performance. Maintain strong productivity levels by catching warning signs early on.

- Inspect for build-up or degradation on areas including runners, molds and barrels, vents, sprues and gates.

- Check nozzles for burrs or scratches that can cause sticking and ensure they are aligned and tightened.

- Examine hardware and connectors for leaks and deterioration, replacing worn parts.

Cleaning

After completion of each run, cleaning should be initiated. Oil, grease and other residue can linger and cause an undesirable outcome.

- Different kinds of resins impact the amount of deposit each may leave behind, so cleansing between cycles is imperative.

- Wipe cavity with a degreaser or solvent using a lint-free cotton cloth.

- Disassemble mold vents and cooling channels to ensure every surface is free of contaminants.

Reference Slide’s Mold Cleaners page to check out our top-notch mold cleaning solutions. Choose the right product for your application. These formulations are specifically designed to eradicate tough resin build-ups, silicone and other impurities.

Lubrication

Proper lubrication abets friction – the number one strain on working parts. Greasing facilitates streamlined production.

- Consider a mold release to prevent part sticking.

- Avoid over-lubrication, as this may attract dust and resin particles.

Lubricating ejector pins is key for preserving injection molding tools. Check out Slide Products Super Grease, available in aerosol and non-aerosol formulations.

Polishing

Polishing of mold cavities inhibits surface defects and upholds mold integrity.

- Opt for a fine grit polishing stone or paste appropriate to utilize on your type of finish.

- Focus on parting lines and cavities where buildup or scratches generally occur.

- Always cleanse after polishing to remove abrasive fragments.

Repair

Small repairs that are caught early avert full-scale breakdowns.

- Replace damaged seals, springs or bushings before they give out.

- Weld or refinish eroded cavities as soon as imperfections appear.

- Work with a certified technician for complete restoration.

Slide Products offers a wide range of MRO products (maintenance, repair, operations) to suit your needs.

Temperature Management

Real-time monitoring of temperature and pressure is essential for tracking and identifying problems on cooling and heating systems.

- Utilize sensors to monitor fluctuations or identifiable changes throughout entire processes.

- Watch for signs of warping or inconsistency from hot spots or uneven cooling.

- Analyze and adjust settings based on data trends when managing machines.

Record Keeping

Checklist used for any maintenance must be readily available and data should be logged appropriately. Mark down notable issues/anomalies to safeguard against future failures.

- Log every inspection, problem, repair and purifying cycle.

- Specify details such as pressure, temperature and irregularities.

- Make use of CMMS (Computerized Maintenance Management Systems) to simplify and refine procedures.

Storage

An often-overlooked step – staying diligent about taking the right precautions for proper storage can make or break an expensive mold.

- Be certain molds are completely dry prior to putting them away as moisture can lead to corrosion.

- Cover them in an additional rust inhibitor to shield from undesirable atmospheric moisture.

- Store in a climate-controlled environment with protective covers.

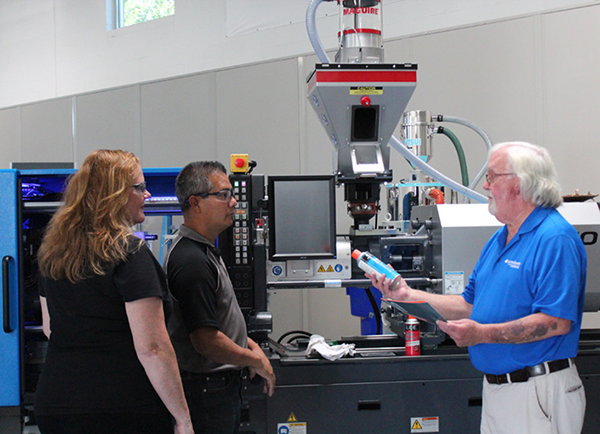

Training

Well-trained operators are at the first line of defense against any manufacturing problems.

- Inform workers about preferred servicing procedures and smart practice methods.

- Educate technicians on new materials, lubricants or applicable maintenance formulas.

- Incorporate comprehensive training courses and review periodically to guarantee consistency.

Slide provides Top Tier Services – free onsite productivity assessments, field support and personal assistance tailored to your operations.

Keep Production Running Smoothly

Performing preventive maintenance is an indispensable practice that can translate directly into cost savings. The benefit of having a well-maintained facility helps create more consistent parts with fewer major failures, resulting in less defective products and extended lifespan on injection tooling components.

At Slide Products, we are committed to helping you find the right solution for your success. If you are unsure about which product works best for your operation, request a free sample so you can try before you buy or get expert advice from one of our knowledgeable reps today.