June 23rd, 2025

June marks National Safety Month, an annual initiative led by the National Safety Council to remind workers of the importance of risk mitigation in the workplace – fostering a culture across all industries. In high-risk scenarios like plastic injection molding, it is essential to reinforce training and protocols. Implementing proactive strategies serve as a measure to protect employees while maintaining efficient productivity.

Identifying Hazards and Enhancing Workplace Safety

The manufacturing process of the plastic injection molding industry is fueled by powerful machinery, complex mixtures, intense speeds and extreme temperatures. Operating efficiently and safely requires identifying threats, assessing risks and implementing check measures to reduce the likelihood of personal injury, equipment damage and other incidents.

Promoting a safe workplace starts with outlining potential pitfalls, understanding how they occur and applying effective strategies that align with safety compliance standards to protect the health of workers. Below are some of the issues commonly found in this method, along with proactive prevention actions to help mitigate them.

Machinery Danger Areas

Operators are often exposed to several critical points on machinery:

- Feeding area

- Barrel cover

- Extruder

- Nozzle

- Mold

- Demolding area

These zones contain the biggest probability of physical, thermal and chemical danger during operations.

Mechanical Hazards

Injection molding machines involve various moving machinery, including powerful hydraulic and robotic systems that generate significant force.

- The clamp and toggle assemblies are among the most dangerous – known as pinch and crush points.

- Hydraulic clamps open and close molds under intense pressure, while the ejection site itself can cause harm if accessed during movement.

Solution

- Implement fixed guards and train operators how to utilize them proficiently.

- Conduct routine inspections on moving equipment, parts and locking mechanisms.

- Equip emergency stops or interlocked doors to halt operation if doors/guards open.

Thermal Hazards

Plastic granules must be heated at extreme temperatures to reach intended viscosity to fill molds, exposing workers.

- Hot barrels and nozzles – items which can cause serious burns.

- Purging accidents encompassing scorching molten plastic that could eject unexpectedly.

Solution

- Wearing appropriate coverings, heat-resistant gloves and protective clothing (PPE).

- Label hot surfaces and allow for cooling periods between handlings.

- Ensure strict purge protocols using approved proper barriers and tools to prevent contact.

Chemical Hazards

Various agents are often used in production including additives, plasticizers and resins that often release toxic fumes when heated.

- Respiratory exposure to VOCs – melting zones can discharge volatile organic compounds and harmful airborne particles within indoor facilities and may cause serious breathing problems.

- Nozzle areas where raw materials injected under great pressure can emit pressurized noxious vapors during production.

Solution

- Install local exhaust systems for effective ventilation above machines and work zones.

- Provide respiratory protection where aeration is not sufficient.

- Use low-emission elements when possible.

Electrical Hazards

With elevated voltage machinery and automated practices in constant use, danger of electrical fire and shock become real.

- Damaged wiring, improper lockout techniques or poorly maintained apparatuses can lead to dangerous failures.

Solution

- Maintain regular inspections and thermal imaging of control panels.

- Train personnel on LOTO (lockout/tagout) protocols for maintenance and troubleshooting.

- Keep electrical panels clean from dust or moisture and replace worn cables promptly.

Ergonomic Hazards

Repetitive movements, awkward postures and manual handling of equipment and workings can potentially contribute to bodily strain injuries.

- Loading material or removing parts in constant recurring cycles.

- Repeated bending and twisting when accessing molds or panels.

Solution

- Rotate workers through different tasks to reduce repetition.

- Redesign workstations for better ergonomic alignment.

- Provide mechanical aids for lifting and repositioning molds or heavy items.

Process Related Hazards

Unpredictable machine behavior, such as injection overpressure or unplanned starts/resets can result in serious accidents.

- Use stress monitoring systems involving auto-shutoff controls.

- Require two-hand controllers to prevent accidental engagement.

- Maintain clear, updated consistent guidelines for safe machine startup and recovery.

Risk mitigation in plastic injection molding isn’t just about checking boxes — it’s about creating a culture where safety is second nature. Understanding the physical, chemical and ergonomic challenges that come with large volume molding allows facility staff to make smart, proactive decisions that protect both people and equipment.

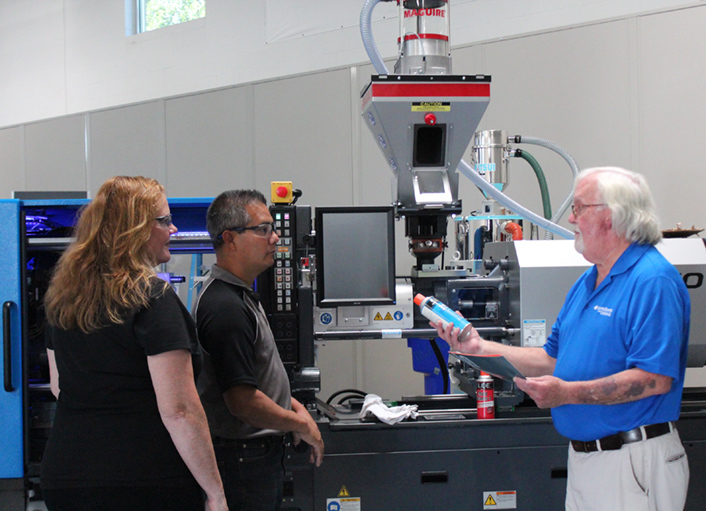

At Slide Products, we offer Top Tier Service safety assessments at no charge, including a full review of safeguarding practices and hazard controls for mold makers and molders. It’s one more way we support manufacturers in running secure, more efficient operations — because productivity should never come at the cost of safety.