September 9th, 2025

In plastic injection molding, consistency and precision are everything. When it comes to the demolding process, an often-overlooked hero is a mold release agent – a product that has become a staple for successful manufacturers for over 60 years. That is why Slide Products emphasizes its importance and offers an array of these formulations. Keep production running smoothly, reduce scrap rates and extend the life of costly components by incorporating it in your production procedures. Let us help you explore the world of mold release formulas and how they can streamline your process:

What exactly does a mold release do?

A mold release helps to ensure that parts don’t stick to the mold cavity, facilitating hassle-free demolding. What it does is act as a barrier between the mold and resin to avoid the two becoming fused together, allowing for a seamless transition. But beyond the primary benefits, some additional advantages include:

- Preventing your pieces from sticking

- Improving on your surface finish for quality results

- Providing you with significant cost savings in the long run

- Protecting your parts from experiencing unnecessary damages

What are the key considerations?

There are many available options, and deciding on a match that works well in your manufacturing setting comes with some parameters to consider. Whether you are handling food grade materials or in search of a specialty formulation for investment wax casting scenarios, there is a suitable product for you. Some factors before finding your best option depend on:

- How you intend to apply (aerosol or liquid form)

- The resin types you’re handling

- The complexity of involved components

- Adherence to regulatory requirements

What are the types of mold release agents?

Understanding the impact each unique mold release has in specific methods can make or break your performance. Here are several choices:

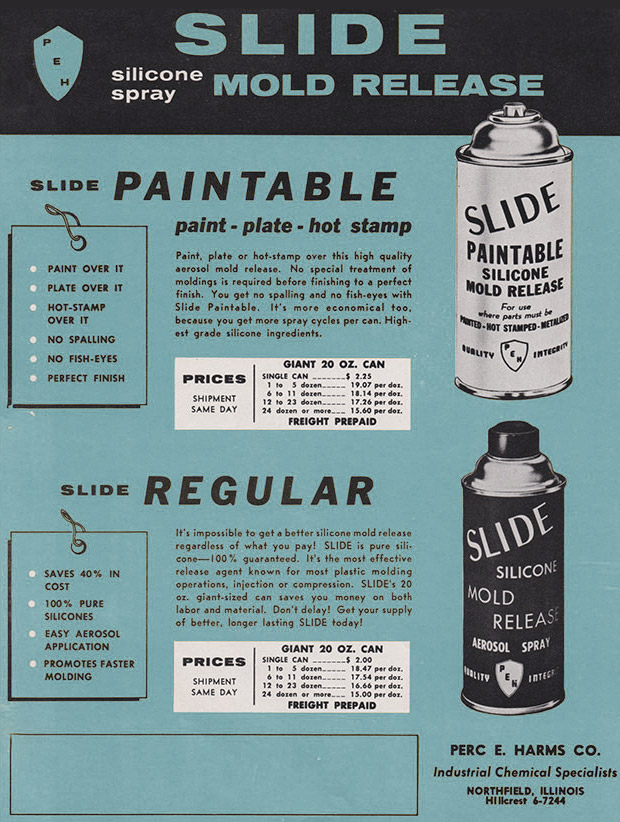

Silicone Oils

- The most universal option on the market, designed with thermal resistant properties

- Available in food-approved, NSF-registered varieties

- Non-paintable and may lessen or prevent adhesion

- Works well in removing rubber, die casting and plastic

Non-Silicone Oils

- Great for painting or post-decorating projects

- Compatible with electronic and food-related molds

- Leaves a glossy finish, with no excess residue

- Excellent for thermoplastic, rubber, plastic, polyurethane and composites

Solvent-Based

- Quick to dry, fast evaporating, perfect for geometrical, complex pieces and applications

- Suitable for high temperatures, humid or cold spaces

- Usually contain many VOCs and flammability content, which require essential ventilation

Semi-Permanent

- A long-lasting coating that can go through multiple cycles

- Helps reduce downtime for high volume production

- Requires a detailed finishing preparation for optimal results

Water-Based

- The main ingredient is water, so less health and safety hazards are involved

- Low VOC properties support environmental standards

- Suitable for concrete, epoxy and polyurethane

Dry Film

- Gets rid of liquid contaminants and doesn’t leave behind wet residue

- Fast drying properties help ward off dust, dirt and debris

- Formulated to be used on deep draw molds, most rubber, thermoplastic, ABS, polycarbonate, nylon and vinyl

Specialty Formulations

- NSF-registered for food safety – perfect for packaging and kitchenware applications

- Boron nitrides withstand extreme temperatures during investment casting, metal die casting and composite molding

- PTFE-based agents made especially for medical devices and electronics, where exterior adhesion is critical

How should I apply?

Less is More

To achieve meaningful results, we recommend that you do a preliminary test and apply a minimal amount initially. This will lessen the possibility of excess burning up and accumulation in the mold cavity.

Proper Distance

Spray from 8-12 inches to achieve full, even coverage. Be sure not to overapply as this is one of the biggest mistakes operators often make.

Start Clean

To allow your solution to bond sufficiently, begin by using a mold cleaner to strip away any buildup and provide a fresh canvas for proper application.

Test

Reapplication time can differ for each product – so to avoid headaches, you should run a trial to determine how often you need to reapply, which generally happens a cycle or two before components begin to stick.

Get Expert Advice

We believe mold agents aren’t just a chemical coating – but paramount for protecting your components, lowering overall costs and operating efficient manufacturing. Choosing the right mold release can make the demolding step faster and more consistent, while also protecting your molds and keeping production running seamlessly. Check out Slide’s Mold Release Agents available to try before you buy.