October 10th, 2023

Existing in a highly technically advanced world and as a rapidly growing society, we are in constant need of materials (such as plastic) which results in mass production. But this leads to the problem of resource scarcity that will inevitably occur. The constant cycle of creation and subsequent disposal of material waste is sending us toward the irreversible destruction of our environment. As both consumers and producers, it's important that we are cognizant of any issues that have evolved yet proactive in aiming for a more economical sustainable approach.

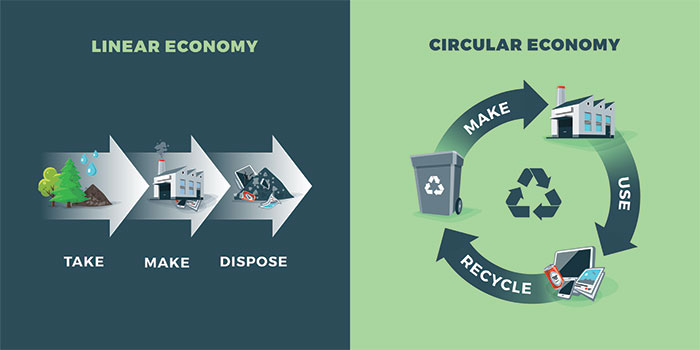

Take, Make, Waste – Cradle to Grave

The term “Cradle to Grave” in a business sense refers to the type of ecological imprint that a product or activity would have from its inception thru to its end-of-life stage (disposal). Simply put, once you decide that you will “take” a resource, “make” (manufacture) something, it then becomes your responsibility to consider what consequential waste or pollution will be left and how it is best managed.

During the creation of certain products, conscientious recycling often is an afterthought and the disposal part of the equation not given enough emphasis. This oversight brings about a rise in hazardous disposal, growing landfills and limitations within our material supply chain.

In 1976, the EPA formerly established a comprehensive regulatory program – Cradle to Grave – under the RCRA (Resource Conservation and Recovery Act), a public law that provides the regulatory structure on how to handle hazardous and non-hazardous waste. In part it states, “By law, those who generate hazardous waste and dangerous goods are legally responsible for managing it safely from ‘cradle-to-grave,’ i.e., it must be safely managed from its origin to its treatment, disposal, or storage.”

Closing the Loop – Cradle to Cradle

Cradle to Cradle (C2C): “Everything is a resource for something else. In nature, the ‘waste’ of one system becomes food for another. Everything can be designed to be disassembled and safely returned to the soil as biological nutrients or re-utilized as high-quality materials for new products as technical nutrients without contamination.”

This is an excerpt from a book published in 2002, “Cradle to Cradle – Rethinking the Way We Make Things” authored by William McDonough and Michael Braungart. These two design chemists trademarked and registered the idea in 2001 and it has been coveted worldwide by companies, organizations and governments ever since. However, as a concept the original credit belongs to a Swiss architect, Walter Stahel, who coined it in 1976 with his co-author Genevieve Reday.

Fortunately, many products made today can be repurposed or are biodegradable. Contrary to Cradle to Grave, this method is a greener process in which goods are initially designed to be reused, recycled or composted at the end of their life without harm to the environment. It can be described as a circular economy, where resources are regenerated until the end of their last life, in time returning to the earth.

This revolutionary theory aims to reintroduce materials back into either a biological or technological cycle. Typically, constituents extracted from a biologic resource would go back to a geological origin. While eco-friendly parts would be repurposed under a tech category. The ideology encourages a nature-inspired path to reuse repeatedly. Results are notable and can positively impact production processes by minimizing the carbon footprint. Choosing to implement logical procedures during product development will minimize negative effects for future generations.

Rethinking and Picking Products with Intention

Plastic is a vital material for consumers, and although Cradle to Cradle is still in its early stages in the manufacturing industry, companies like Slide Products are becoming more and more conscious of their manufacturing practices and want to encourage life past production in union with innovation. Instead of designing things with no forethought about how to handle resulting trash, Slide prefers to integrate a sound disposal plan during the beginning stages of our formulations.

Slide’s Contribution to a Greener Future

Slide is constantly revisiting ways to advance new products and strives to eliminate all hazardous waste. One of our solutions for waste management is SHARP (Slide Hazardous Aerosol Return Program). This initiative allows customers to return used aerosol cans to be properly recycled.

Similarly, the refillable cylinder program reduces HAZMAT refuse in addition to reduced disposal costs. And our partnership with One Tree Planted has helped to restore forestation by contributing well over 2,000 trees planted in 2023 alone. Learn more about Slide’s environmental commitment.